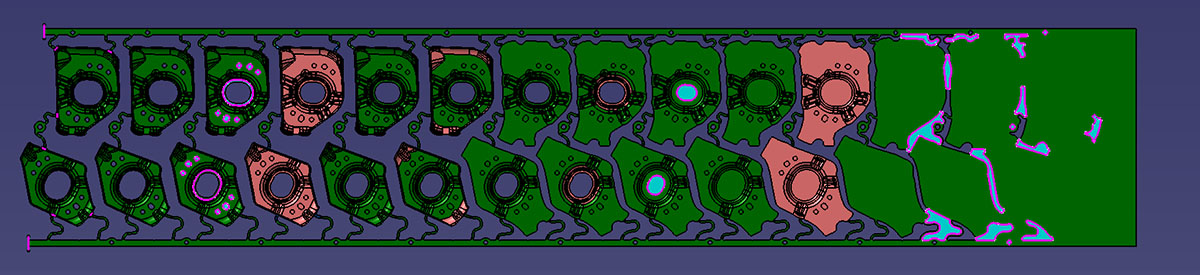

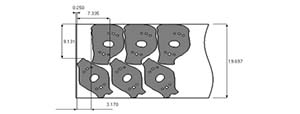

The designed complete material strip diagram, the material utilization rare is very high and the waste is relatively sall.

Two different parts are put together to form a continuous mold

Superiority

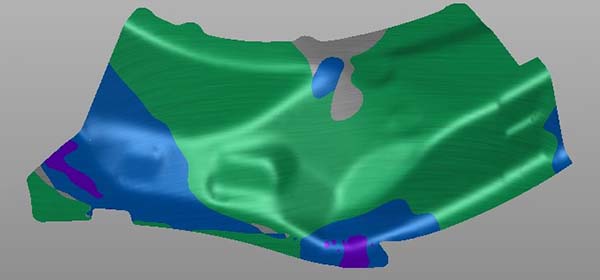

Customer concern: The plate has sagging condition.

Solution: We cut a sheet to measure the sagging condition, According to this situation, it is only necessary to increase the floating height of the mold by 18mm during mold design.

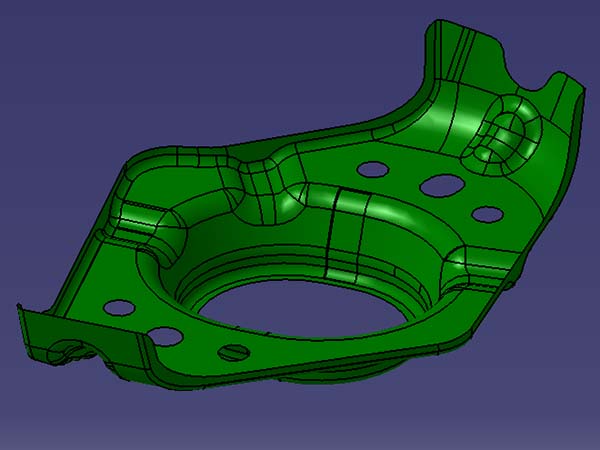

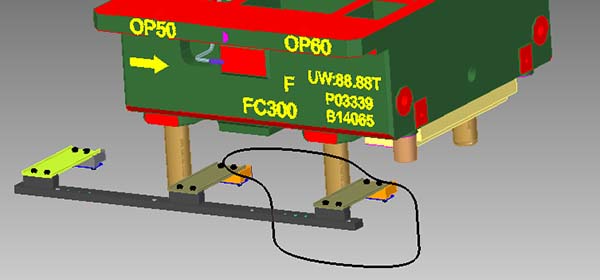

Regarding trasnfer tool, especially with deep drawing technology is our advantage.

During design and simulation process, beside forming simulation process, we are also available for supporting gripper system development including collision curve simulation.

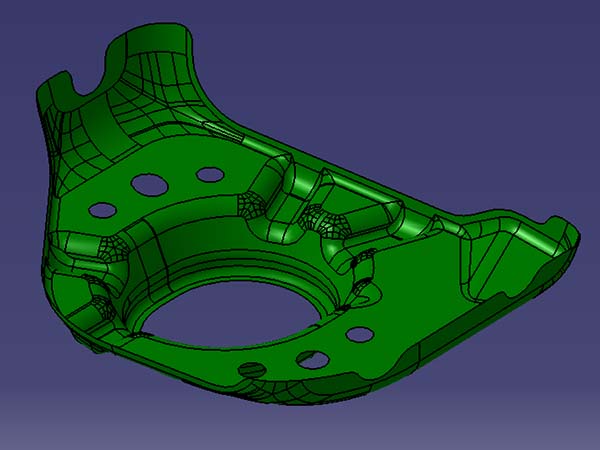

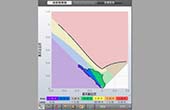

1. Analyze the stamping process of the mold and analyze the molding process of 3D molded parts through 3D software.

2. Calculate the material expansion of product parts for nesting.

3. List the steps of continuous die or the number of engineering die.

4. Calculate the punching force of die face size.

5. Continuous and automatic production is difficult for conventional stamping processes.